“Watch Your Clearance” and Other Rules for Transporting Your Forklift

As most forklift operators will attest, safely using a forklift requires both knowledge about forklift safety procedures and experience in handling the vehicle. But what about transporting a forklift to a remote job site?

While many forklifts are used primarily within a defined workspace such as a warehouse or manufacturing facility, in some instances a forklift must be transported off-site. When this is necessary, a new set of safety rules come into play.

Forklifts Aren’t Licensed for Road Use

Even if the remote work site is close to the forklift’s home facility, the vehicles are not street legal or licensed, so they should never be driven along public roads or highways unless part of an assigned work project.

Because the average forklift weighs about 9,000 pounds and uses hard wheels, they potentially can cause damage to the road surface. If so, the vehicle’s owner may be responsible for repairs.

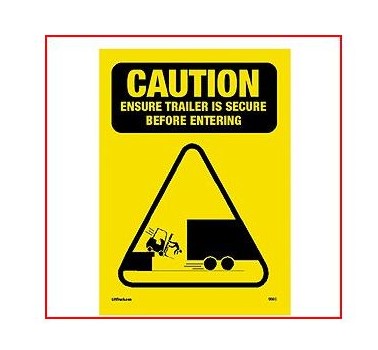

Tractor-trailer rigs or flatbeds are commonly used to move a forklift from one location to another. To safely transport the forklift using atop another vehicle, make sure that the flatbed or rig you are using is rated for the weight capacity of the forklift. If you are loading a trailer that is not attached to a tractor, you will need to put a nose jack under the front of the trailer to prevent it from tipping. Adjust the nose jack so that it is within an inch of contact with the trailer.

Where to Position the Forklift

Once you are sure it can handle its weight and the nose jack is in place, back the forklift onto the bed surface. Most of the forklift’s weight is concentrated behind the driver’s seat, so you always want the forks to be pointed toward the rear of the rig or flatbed. This is to maintain the center of gravity toward the middle of the rig, rather than at the back end.

It’s also a safety precaution in case of a collision during transport. If the tines are pointing forward, they could penetrate the cab.

Make sure the forklift is centered on the transport and that the tines are lowered all the way down to the surface. Tilt the tines forward slightly before they touch the floor.

Once the forklift is in place, secure its wheels using chocks to prevent it from rolling during transport. If the transport doesn’t already have pre-drilled bolts for chocks, place wood blocks behind each forklift wheel and use 4-inch screws to fasten the blocks in place.

Disconnect Battery to Prevent Explosions

For propane-fueled forklifts, disconnect the propane tank before transporting the vehicle. If it’s a gasoline- or diesel-powered forklift, check to make sure the tank is secured and that no fuel can splash out of the tank while the forklift is being moved. Always disconnect the battery terminal to prevent arcing.

Now it’s time to secure the forklift to the flatbed with chains and come along. Secure the chains or nylon straps to the edges of the truck bed then tighten the come-along so that the forklift can’t move. Use at least two chains to create four anchor points, one at each corner of the vehicle.

Watch Your Clearance

Finally, before you transport the forklift, check the clearance of your vehicle. If the top of the forklift is higher than the cab, you will need to take this into account to prevent crashing into an overpass or bridge. Be aware of your clearance and make sure you have enough distance to safely pass beneath any overhead structures throughout the entire course of the transport.