Load Handling And Composition On A Forklift – Part IV: Balance

In Load Handling And Composition On A Forklift – Part III: Maximum Load Moment, we defined Maximum Load Moment and described weight distribution and how it can change the weight of the load a forklift carries.

In this article, we will discuss Balance.

Keeping the forklift balanced is essential to preventing accidents especially tipping over and falling loads. Two factors affect forklift balance –- center of gravity and shifting center of gravity.

Center Of Gravity

Knowing the center of gravity of the load will allow the forklift operator to distribute the weight of the load evenly when carrying irregular sized loads. The goal is to keep the center of gravity of the load as near to the center going horizontally across the forks and as near as possible to the front wheels.

Center of gravity is defined as the point on an object where all of the object’s weight is focused and all of the parts balance each other. For symmetrical loads, the center of gravity is at the middle of the load in terms of the load’s length, width, and height. Since the capacity of the forklift is assumed to be a cube, having the center of gravity in the middle, the shape and position of the load are key when determining whether or not a particular load can be carried safely.

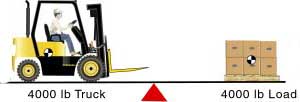

A 4,000-pound forklift is balanced by a 4,000-pound load. (Graphic courtesy of OSHA)

Once a load is on a forklift, the key to ensuring that it is safe to carry is the combined center of gravity of the load and lift.

For example, a common unloaded forklift weighing 4,000-pounds may have its center of gravity about 10-inches above and 2-feet behind the front axle, about half way up the lift’s body. The heavy counterweight located toward the rear of the lift places the center of gravity toward the rear. This ensures that the forklift will not tip forward. When you include a 4,000-pound load consisting of a cube with event weight distribution has the center of gravity in its center. With the load on the lift, the combined center of gravity of the lift and load moves forward. The forklift will not tip over as long as the weight of the load is centered and does not exceed the capacity stated on the lift’s data plate. However, if the load is too heavy, or if it is placed at the end of the forks so that the load center distance is increased, the excessive load moment will cause the forklift to tip forward. Keep in mind that when the forklift contains a load, the combined center of gravity of both the load and the lift shifts forward from the center of gravity of the unloaded forklift.

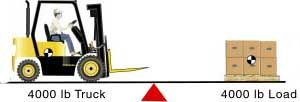

The center of gravity of the load and lift shifts forward toward the front wheels as the load is engaged. (Graphic courtesy of OSHA)

So the forklift operator needs to be cautious about a possible tip over or of falling loads when driving and depositing a load. That is because the center of gravity can shift.

So a forklift operator is encouraged to:

• Handle loads within the capacity of the lift as stated on its data plate.

• Not operate a lift if the back wheels begin to lift off the ground. This is a sign that the lift is overloaded and that the center of gravity has shifted too far forward over the axle of the front wheels.

• Handle only stable or safely arranged loads. Be extremely cautious when handling off-center loads that cannot be centered.

• Never drive the lift with the load elevated. Elevating the load increases the load center distance because the center of gravity has shifted upward and forward.

• Adjust long or high loads that are multiple-tiered. This can affect the lift’s capacity.

• Keep the center of gravity of the load as low to the ground and as close to the front wheels as possible.

It is recommended that the load be carried 4 to 6-inches from the ground, that you tilt the mast back and position the heaviest part of the load against the carriage, and that you travel with the mast tilted back to stabilize the load.

(Source: OSHA)